Nippon Nozzle Spinnerettes

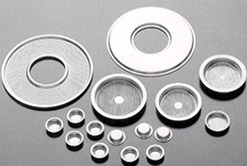

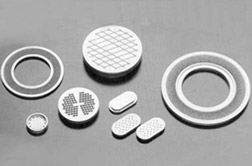

Spinnerettes (aka Spinnerets)

The spinnerette inspection equipment is an automated measuring and inspection system. It identifies out of specification capillaries, blows air to clear holes, and reinspect and identifies ad G or NG. The system is designed to load multiple spinnerettes into a tray, program it and complete testing unattended. Measurements made can be for new and used spinnerettes and tracked for capillary changes.

Dry Spinning Spinnerettes

In dry spinning, the fiber-forming substance is melted for extrusion through the Spinnerette. Solidification is then achieved by evaporating the solvent in a stream of air or inert gas. Acetate, acrylic and spandex can be produced by this method.

Wet Spinning Spinnerettes

Wet spinning is used for polymers that need to be dissolved in a solvent first. The Spinnerette is immersed in tanks containing the solvent into which the filaments are extruded. Acrylic, vinyl, and rayon are produced by this method. Furthermore, Carbon Fiber can also be produced by this process. Carbon Fiber is a fibrous carbon material and can be classified into PAN-based, pitch-based and rayon-based. We also feature Carbon Fiber and PAN Polymerization plants, pilot plants, and equipment.

Melt Spinning Spinnerettes

In melt spinning, the fiber-forming substance is melted for extrusion through the Spinnerette and then directly solidified by cooling. Nylon, Olefin, and Polyester are produced in this manner.

Laser Capillary Machine

Nippon Nozzle’s new high precision, high speed micro processing laser machine provides production capability to produce various irregular capillary designs. With no thermal deformation due to sublimation and decomposition of the material, the machine enables a clean finish of the machined surface.

Target materials: Iron, aluminum, carbide, stainless steel, ceramics, etc. Repeatability accuracy: ±1μ.

Ultrasonic Cleaner

Using both multiple wave oscillation and high to low frequencies simultaneously, this equipment successfully removes foreign matter in a short time period. Stem includes temperature control, cleaning fluid circulation and filtration. In addition, a vacuum degassing can be included.

This technology removes foreign matter from spinnerette capillaries, filters cartridge media and removes other pack parts. Systems can be customized according to customer needs.

Contact Frankl & Thomas

Please note that we do not list all of our products online. If you don’t see a product you’re looking for, please Contact Us.